Single-Wall HDPE Pipes (PE80 & PE100) for Potable Water Transmission Systems

Table of Contents

Introduction

Single-wall High-Density Polyethylene (HDPE) pipes in PE80 and PE100 grades are the core material used in potable water transmission, municipal water distribution, agricultural irrigation, and long-distance rural water supply systems. Their combination of long service life, exceptional hydrostatic strength, flexibility, corrosion resistance, and excellent hydraulic performance makes HDPE pipes the preferred choice for engineers working in the water industry.

This page provides a complete technical reference for PE80 and PE100 single-wall pipes specifically for water applications, including standards, SDR/pressure ratings, installation guidelines, and downloadable

What Are PE80 and PE100 HDPE Pipes?

PE80

A medium-strength HDPE grade designed for moderate pressure applications.

Commonly used for:

Agricultural irrigation

Secondary water distribution lines

Low-to-medium pressure potable water systems

PE100

The enhanced next-generation HDPE grade with:

Higher Minimum Required Strength (MRS = 10 MPa)

Higher long-term hydrostatic resistance

Higher crack resistance (ESCR)

Reduced wall thickness for the same pressure rating

Longer expected service life (50–100 years)

Because of its superior mechanical profile, PE100 is now the global standard for water transmission mains.

Applications In The Water Industry

PE80 vs. PE100 — Technical Comparison for Water Applications

| Parameter | PE80 | PE100 |

|---|---|---|

| Minimum Required Strength (MRS) | 8 MPa | 10 MPa |

Long-term hydrostatic strength | High | Very High |

| Wall thickness at same PN | Thicker | Thinner |

| Weight | Heavier | Lighter |

| Hydraulic efficiency | Good | Superior |

| ESCR | Moderate | Excellent |

| Service life | 50 years | 50–100 years |

| Best use | Secondary networks | Primary mains, long-distance and pressure lines |

International Standards for HDPE Water Pipes

HDPE water pipes must comply with strict international standards to ensure safety, durability, and potability. Below is a detailed engineering explanation of each standard.

ISO 4427 — HDPE Pipes for Potable Water

- What ISO 4427 covers:

- Dimensions, tolerances, and wall thickness

Physical and mechanical requirements Pressure class PN requirements

Testing methods including:

Hydrostatic pressure tests

Long-term creep resistance

Oxidation Induction Time (OIT)

Melt Flow Index (MFI)

Tensile strength tests

- Water-related requirement:

ISO 4427 only approves materials that meet potable water health regulations, including extractables

EN 12201 — European Standard for PE Water Systems

Key details:

Pipe mechanical performance for pressure lines

Lifetime classification under 20°C and 40°C

Peel strength for electrofusion fittings

Material qualification tests (PE80/PE100/PE100-RC)

EN 12201 is widely used in the Middle East and Europe for water quality and structural safety.

AWWA C906 — American Standard for Large-Diameter HDPE Water Pipes

Covers potable water pipes from 4 inch to 65 inch diameter.

Technical focus:

Chlorine/chloramine resistance

Surge pressure allowances

Fatigue resistance

Requirements for butt fusion and electrofusion joints

Highly recommended for large-diameter water transmission pipelines.

INSO 14427 — National Iranian Standard

Covers:

Dimensional tolerances

Minimum OIT values

Hydrostatic testing at 20°C & 80°C

Material qualification for PE80/PE100

Used by all major water authorities in Iran.

Technical Properties of PE80 & PE100

Material Physical Properties

Property | Typical Range |

|---|---|

Density | 0.945–0.965 g/cm³ |

Melt Flow Index | 0.2–0.4 g/10 min |

Tensile Strength at Yield | 19–32 MPa |

Elongation at Break | >350% |

ESCR | Excellent (PE100 > PE80) |

Thermal Conductivity | 0.4–0.45 W/m·K |

| Oxidation Induction Time (OIT) | > 20 minutes (per ISO 11357) |

Performance Properties for Water Applications

Smooth internal surface (C = 150–160) → extremely low head loss

Corrosion-proof in chlorinated or mineral-rich water

High surge pressure absorption due to elasticity

Excellent seismic performance due to ductility

Resistant to UV when carbon black is added (commonly 2–2.5%)

Hydrostatic Strength Testing (ISO 1167)

The pipe must pass:

80°C @ 5h

80°C @ 165h

20°C @ 100h

With no failures or deformations.

Crack Resistance (ISO 13479 / FNCT)

PE100 is highly resistant to slow crack growth (SCG), making it ideal for long-term water projects.

SDR & Pressure Ratings for Water Pipelines

| SDR | PN Rating | Water Industry Use |

|---|---|---|

| SDR11 | PN16 | High-pressure mains / pumping |

SDR13.6 | PN12.5 | Municipal distribution |

| SDR17 | PN10 | Most common for potable water |

| SDR21 | PN8 | Low-pressure or gravity-assisted lines |

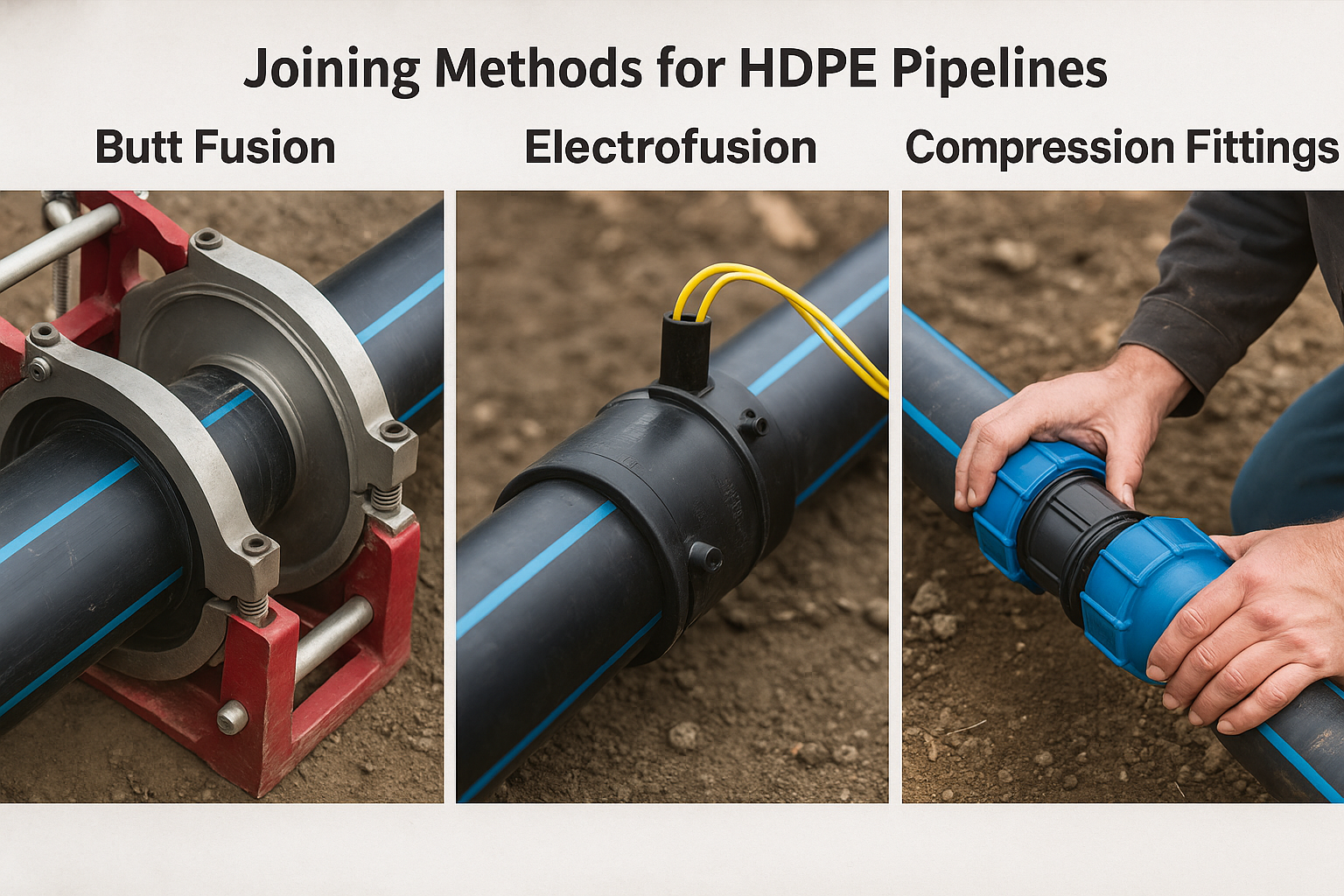

Joining Methods for Water Pipelines

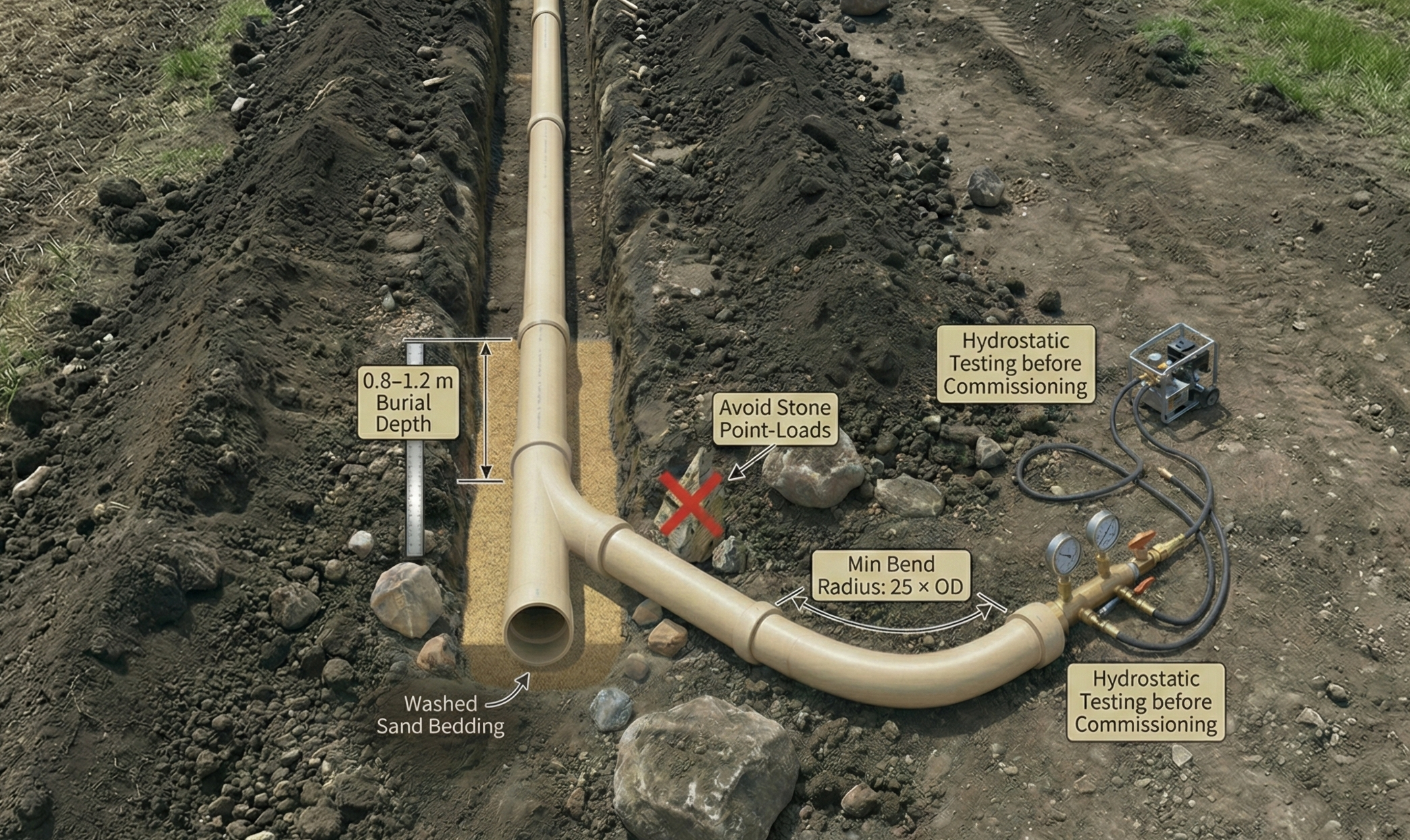

Installation & Design Guidelines

FAQs

Yes, PE100 is certified for potable water under ISO 4427 and EN 12201.

Yes—especially for agricultural irrigation and secondary distribution lines.

We accept payment via credit card (Visa, MasterCard, American Express), PayPal, and bank transfer.

Related Water Products

Iron and Steel Valves

Polyethylene Fittings

Cast Iron and Steel Fittings