Polyethylene Fittings for Reliable Infrastructure

At Azaraksh Novin Mehregan Javid, we understand the critical role polyethylene fittings play in water pipeline infrastructure. Our fittings are engineered for superior performance and long-term reliability, ensuring efficient and safe water distribution. We adhere to the highest industry standards, providing you with fittings you can trust for every project.

Our Commitment to Global Standards in Polyethylene Fittings

- High Global Standards: At Azaraksh Novin Mehregan Javid, we adhere to the highest global standards for our polyethylene fittings.

- Quality and Performance: This commitment ensures that our products meet stringent quality and performance criteria, providing reliable and safe solutions for water pipeline projects.

- Standards Compliance: We prioritize compliance with ISO, ASTM, EN, and relevant local standards to guarantee customer satisfaction and project success.

ISO 4427 Compliance

Our polyethylene fittings are manufactured in strict accordance with ISO 4427, ensuring they meet the highest standards for potable water supply. This guarantees durability and safety.

ASTM D3035 Standards

We adhere to ASTM D3035 standards, ensuring our fittings meet the requirements for dimensions, materials, and pressure ratings. This guarantees reliable performance in various applications.

EN 12201 Certification

Our fittings are certified under EN 12201, confirming their suitability for water supply systems and compliance with European standards. This ensures long-term performance and safety.

Our Rigorous Testing Ensures the Quality of Our Fittings

At Azaraksh Novin Mehregan Javid, we prioritize the quality and reliability of our polyethylene fittings. Our rigorous testing procedures, including mechanical and pressure tests, guarantee that our products meet and exceed industry standards. We are committed to providing our clients with fittings they can trust for long-term performance.

Tensile Strength Testing

We conduct tensile strength tests to determine the maximum stress our polyethylene fittings can withstand before failure. This ensures the fittings can handle the expected loads and stresses in pipeline applications.

Impact Resistance Assessment

Hydrostatic Pressure Testing

Hydrostatic pressure testing verifies the ability of our polyethylene fittings to withstand internal pressure without leaking or failing. This is a critical test for ensuring the long-term integrity of pipeline systems.

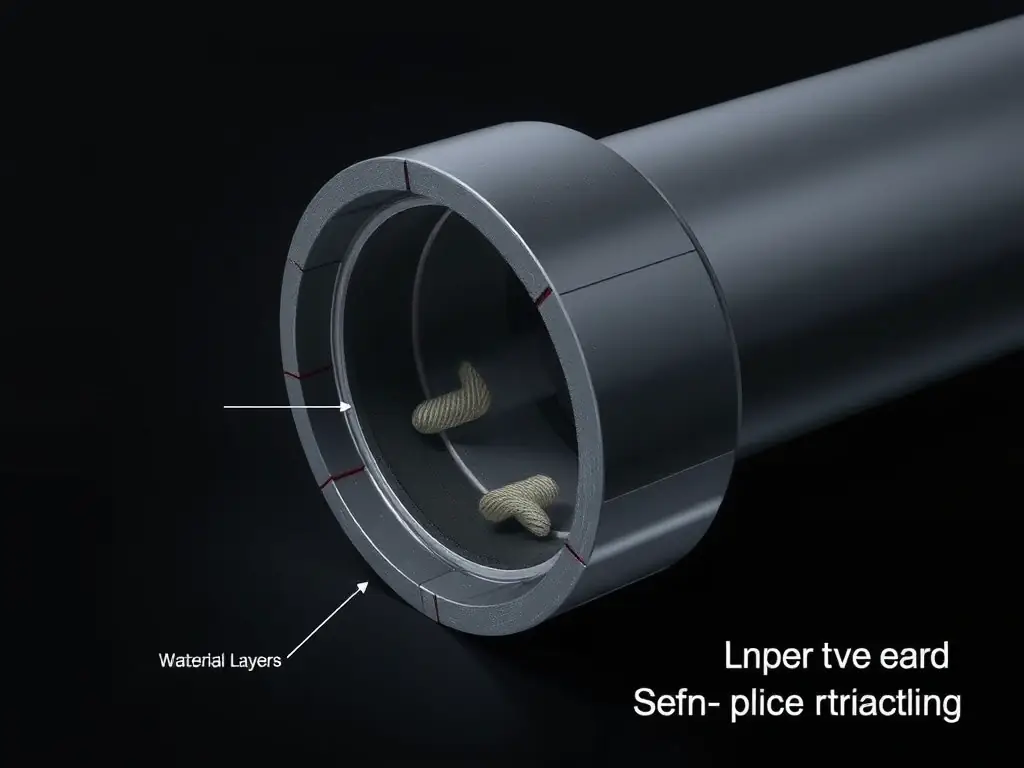

Explore Our Polyethylene Fittings' Technical Specifications

Our polyethylene fittings are engineered to meet the rigorous demands of water pipeline systems. Below, you’ll find detailed specifications covering sizes, pressure ratings, material compositions, and temperature ranges, ensuring optimal performance and longevity for your projects.

Size and Dimensions

Our fittings come in a wide range of sizes, from 20mm to 630mm, catering to diverse pipeline requirements. Each fitting is manufactured with precision to ensure accurate dimensions.

Pressure Ratings

Engineered to withstand high-pressure environments, our polyethylene fittings boast pressure ratings from PN6 to PN25. This ensures reliable performance in demanding water pipeline applications.

Material Composition

Crafted from high-quality polyethylene compounds, our fittings offer exceptional resistance to corrosion, chemicals, and UV radiation. This ensures long-term durability and reliability in various environmental conditions.