Polyethylene Granules: An Overview

Chemical Stability

Resisting Harsh Environments

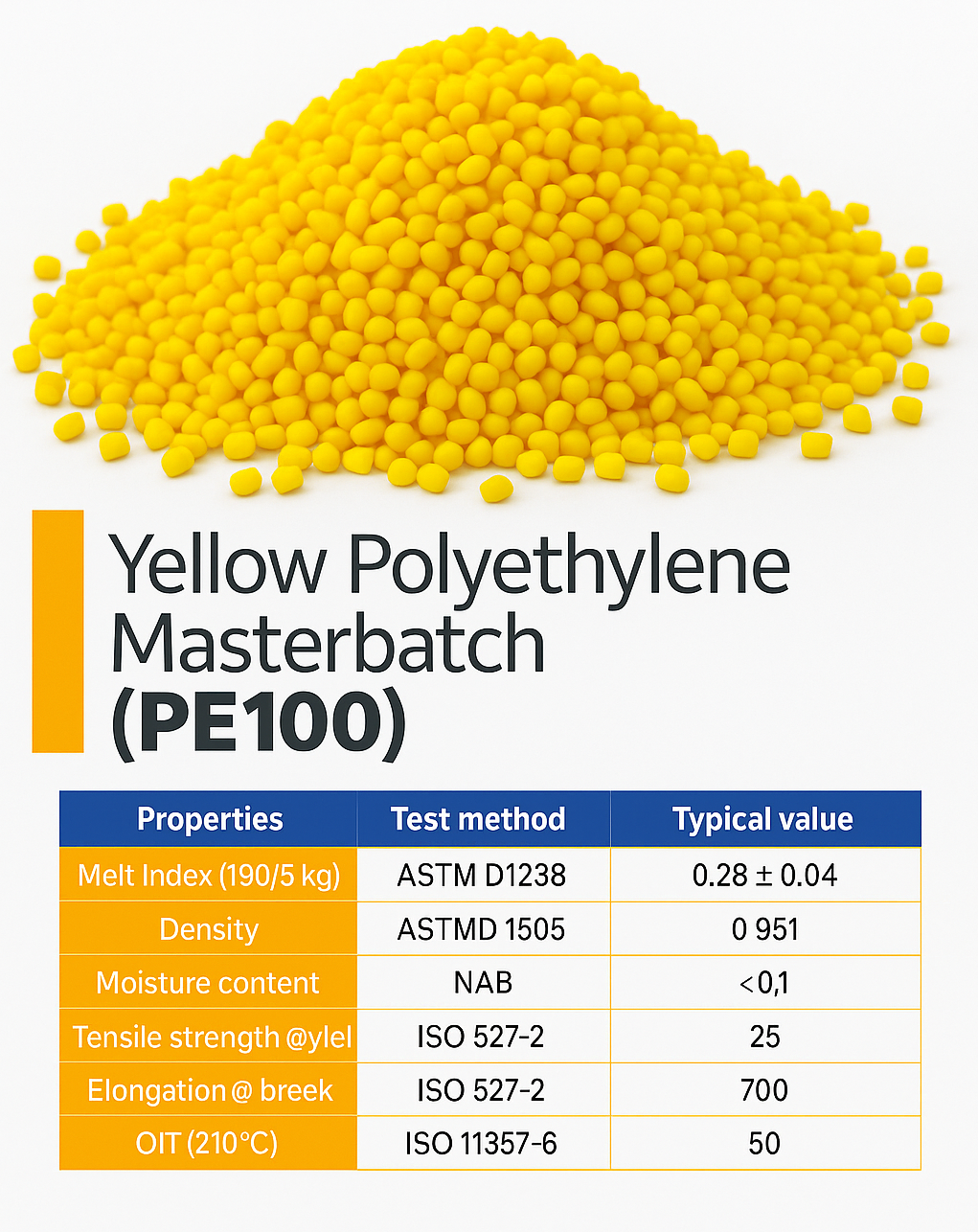

Yellow Polyethylene Masterbatch (PE100)

Overview:

The yellow polyethylene masterbatch is a polymer mixture used to color raw polymers during manufacturing at different concentrations. It has a high content of pigments.

Composition:

This mixture is comprised of a parent polymer (high–density polyethylene) and some additives, such as antioxidants and pigments. It comes in a granule form and is employed as a strip indicator of gas pipes and the inner wall of corrugated pipes.

Applications:

The yellow masterbatch is eco–friendly and suitable for gas distribution pipes and corrugated wastewater pipes.

Features:

It comes in a bright color and has a high density, perfect dispersion, and a stable color and size. It is effectively checked in the R&D Department, producing a product using a variety of formulations to…

Black Color Compound (CRP 100 Black)

Overview:

Black color compounds are widely used in pipe manufacturing. Raw polyethylene granules were used in combination with black masterbatches to manufacture polyethylene pipes in the past.

Previous Method and Its Limitations:

However, there were disadvantages, such as a heterogeneous black pigment distribution, which reduced pipe quality and shortened the lifespan. Although this strategy is still adopted for manufacturing pipes, it is emphasized that black color compounds are to be employed to produce polyethylene pipes, particularly gas pipes of more strict safety.

Our Product – CRP 100 Black:

Caspian Louleh Co. produces the black color compound CRP 100 Black using advanced manufacturing systems to offer high-quality products at international standard levels.

Base Polymer and Performance:

PE 100 is used as the base polymer in the black compound, which makes it an efficient and effective product.

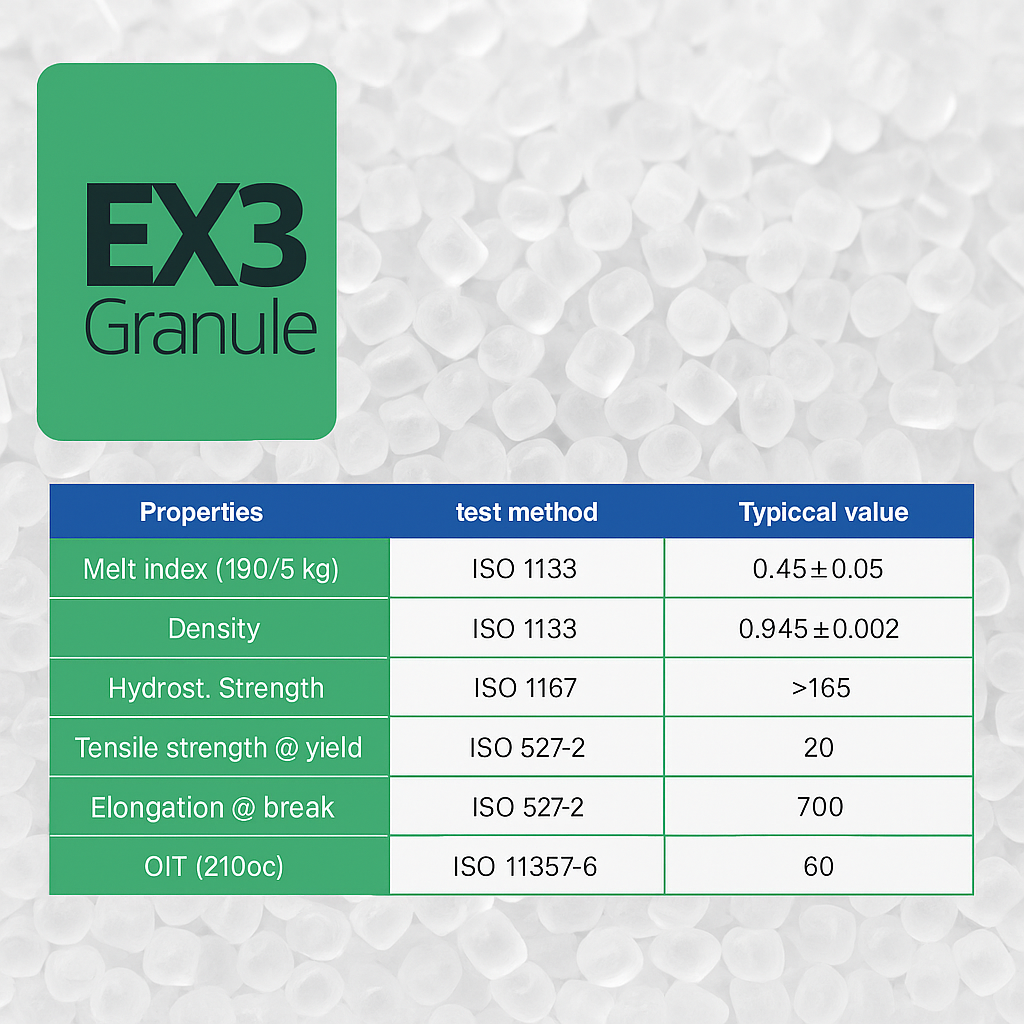

The EX3 Granule

Description

- The EX3 granule is among the most commonly used granules. It is a high-density polyethylene granule used to produce a variety of plastics. EX3 is also known as the high-density extrusion granule since it is most often employed as a raw material in extrusion manufacturing processes.

EX3 Production

- EX3 polyethylene is a colorless high-density polyethylene type of class PE80. It is fabricated through ethylene polymerization. Density, MFR, crystallinity, branching degree and cross-linking, molecular weight, and molecular weight distribution can be controlled using catalysts and the polymerization technique.

EX3 Granule Properties

- EX3 is a high-density extrusion polyethylene that is molded using injection molding. It has excellent durability, compressive strength, and stiffness. Therefore, EX3 products show high impact and tensile strength. EX3 has superb chemical resistance and does not react in chemical settings. Polyethylene of different grades is employed to produce additive, color, and filler masterbatches.

Compound 3840 (PE 3840)

Product Overview

Polyethylene 3840 is used to manufacture water and chemical tanks and, in general, in roto molding systems to produce tanks. This polymer is bright and provides an excellent base for color customization.

Usage and Application

Polyethylene tanks made from Compound 3840 are used in various climates and are sometimes exposed to sunlight. Therefore, it is required to combine Polyethylene 3840 with pigments and other additives to achieve the desired color and ensure durability under different environmental conditions.

Color Options

Companies often add white, blue, black, and red pigments to Compound 3840 to create a variety of colors suitable for different tank applications.

Manufacturing Process

For use in roto molding systems, Polyethylene 3840 must be combined with pigments and additives during extrusion, followed by powdering the resulting granules so that the compound can be used effectively in the molding process.

Production and QualityCaspian Louleh Co. has conducted extensive research on producing raw materials and compounds, fabricating Compound 3840 in various colors and powder forms suitable for roto molding systems.

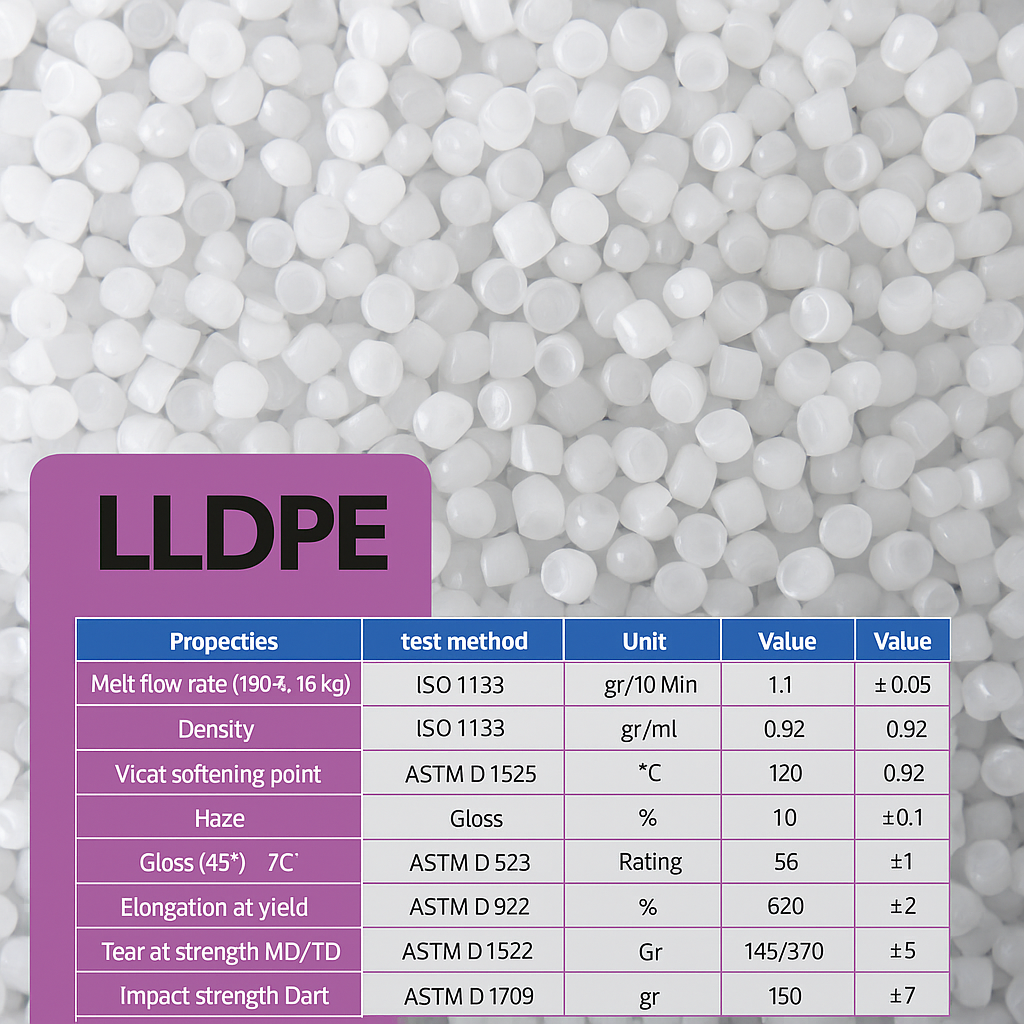

LLDPE

- High Thermal Stability: Ensures consistent performance.

- Moisture Resistant: Prevents degradation.

- Lightweight: Simplifies installation.